Most Service Managers are "under-appreciated".

What is wrong with Service Management at most dealerships?

Too many times I have heard senior managers who work for an equipment dealerships say that "the Service Department is a necessary evil.

They exist to take care of warranty issues and nothing more".

I find that to be a wrong-headed way of thinking. Fortunately the dealerships where I have worked had much higher expectations.

They expected me to produce 25% net operating profit year after year.

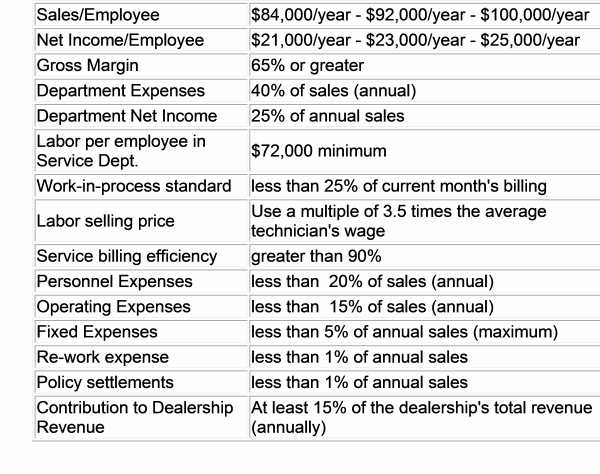

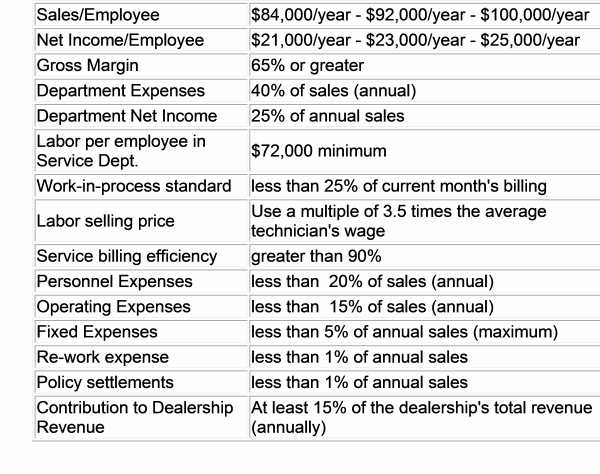

I used the Key Financial Standards below as a guide to achieve the net operating profit.

Key Financial Standards

Let's Do A Brief Review Of The Financial Standards

That The Top-Tier Dealerships Use.Sales/Employee: Range from $84,000 to $100,000 per employee.

How do we get there?

Identify where your Service business is coming from today.Create a simple Excel spreadsheet that shows the top 20% of customers who generate most of your Service department revenue.

Set a schedule to visit customer to ask for more business. Give the customer the reasons why this is an advantage for them.Increase Customer Support Agreements by selling them at point-of-purchase;train your sales force how to sell Customer Support Agreements.Selling Flat Rate repairs (70% of all repair work in the shop; 50% of all repair work done in the field)>/li>Perform a walk-around inspections on every customer job brought into the shop (pre and post repair with a written report).Sell “resident technicians” time at a reduced rate to remote customers.Use “Shop-Cost-Analysis” to sell against customer’s use of own mechanics. Over 50% of Service department competition is from the customer doing Service work that belongs to YOU!

Gross Margin Must be 65% or greaterHow do we get there?

DO NOT “flat rate” price a job when you need to reduce billing; this is a price adjustment not a flat rate. Charge the hours worked to the correct category. If there is unapplied time, on-the-job-training, shop clean up, etc. charge the hours to the correct expense category.

Schedule the correct technician to do the job whenever possible. Create a mentoring program to allow a senior (competent) technician to train, coach and guide a less experienced technician

Work in Process (WIP) must be less than 25% of current month billingHow do we get there?

Reduce the number of steps to open and close work orders. Complete a process review to find wasted time.Close work orders daily versus waiting for the last week of the month.Simplify the sublet process; get bills for sub-contract work with in 10 daysEstablish a 30 day cutoff on disputed invoices; problems work orders “never get better with age”

Establish Selling Price of Labor Per HourThis is a simple calculation: Use a Wage Multiple of 3.5 times the average labor rate for all technicians. Establish the selling rate for mileage and travel timeIncrease the number of flat rate price repair jobs.Establish correct labor selling rate; remain competitive however, do not fear being the price-leader

Billing Efficiency must be greater than 90%How do we get there?

Assign the correct technician for the jobProvide clear, concise instructions prior to the repair being performed (use the 3-C’s method: Complaint, Cause, Correction)Assign work to technician for no more than 8 hours.Follow up with technician to determine progress on the job prior to the 8 hour limit established above

Arrange for the proper tooling and technical information to be available prior to assigning workReview parts deliveries for repairs with Parts Managers on a daily basis.

In This Section We Will Discuss All Service Department Expenses. These Expense Include Operating,Personnel, and Fixed Expenses.

Personnel Expense must be less than 20%.How do we get there?

Use clearly defined position descriptions for all personnel to drive maximum job efficiencyCreate a budget for personnel and stick to itOperating Expenses<15%How do we get there?

Set realistic expectations based on current activity levels not just historical information.Create a budget plan and stick to it. Fixed Expenses<5%How do we get there?

Review all capital expense items every six months with senior management.Create a replacement schedule based on depreciation (book value) and current condition of asset,

Rework Rate must be less than 1%How do we get there?

Assign the correct technician to the job. Establish a "technical-competence" rating system to know at what level a technician is at the time.Provide clear, concise, written instructions a the beginning of every job (AVO – Avoid Verbal Orders)Follow up daily on the progress of the job.Create a mentoring program for less experienced technicians

Review the reasons for the re-work with the technician (document the discussion)

Policy Settlements/Commercial Settlements

must be less than 1% of Sales Revenue.How do we get there?

Get maximum recovery on warranty/policy settlements – use the 3-C’s to support your caseTake a customer’s point-of-view. Ask yourself if you would feel as though you have been treated fairly before you reach a settlement with the customer.Settle policy adjustments with the customer and then do battle with the manufacturer for support. The customer is “your-customer” not the manufacturers.

What Should The Service Department Contribute To Overall Sales Revenue for the dealership.The "Top-Tier" Dealers have the following breakdown of Sales contribution for each department:

Service Revenue should be 15% or greater of total sales revenue for the dealership.Parts Revenue should be 15% or greater of total sales revenue for the dealership.Machine Sales Revenue should be 15% or greater of total sales revenue for the dealership.

Thank you for viewing the Service Management page. Please click here to return to the home page of Equipment Dealer Secrets